Artificial Intelligence (AI) is reshaping the way consumer-goods companies plan, operate, and make decisions.

It has evolved into a structural capability that integrates data, automates decision-making, and elevates performance across the entire value chain with greater precision.

Its application spans from demand forecasting to intelligent management of consumer experience, enabling operating models that are more robust, efficient, and aligned with clear value-creation metrics. This integration is driving an evolution in ways of working, transforming how organizations structure teams and processes, toward a more systematic, evidence-based approach, with management that is less tactical and more forward-looking.

The following outlines how AI is transforming each stage of the value chain.

By leveraging historical data, POS signals, weather, seasonality, and promotions, models identify early demand shifts and translate variability into actionable recommendations, adjusting production, distribution, and coverage before deviations become operational issues.

Use cases: signal detection, scenario simulation, prescriptive recommendations.

Typical impact: improved forecast accuracy (MAPE/Bias), fewer stock-outs (OSA), and more stable inventory levels (DOH).

Consumption, inventory, internal capacity, and supplier constraints are connected to project requirements and dynamically recalculate replenishment under changing assumptions. The result is a planning process that is less rigid and more responsive to availability, priorities, and actual capacity.

Use cases: requirements projection, replenishment calculation, dynamic purchasing prioritization.

Typical impact: higher fill rate, lower total inventory cost, and reduced back orders.

Rotation, variability, lead times, and logistics costs are combined into differentiated policies by SKU and location (safety stock, reorder points, lot sizes), balancing service levels and working capital without increasing obsolescence.

Use cases: advanced ABC/XYZ segmentation, multi-objective optimization, network-level policies.

Typical impact: higher service levels, lower excess and obsolescence, and improved inventory turnover and working capital.

When demand, capacity, or constraints change, advanced analytics anticipate bottlenecks and reconfigure flows across nodes through disciplined decisions, sequencing, allocations, and internal routing that balance cost and service levels.

Use cases: tactical network planning, flow reallocation, constraint-based prioritization.

Typical impact: shorter cycle times, improved resource utilization, and more consistent SLA compliance.

Replenishment parameters move away from static settings and adjust based on real consumption, seasonality, availability, and market conditions to ensure continuity without oversizing inventories.

Use cases: automated min/max adjustments, frequency recommendations, delivery window optimization.

Typical impact: fewer stock-outs, reduced manual workload, and greater operational continuity.

Slotting and picking are optimized using rotation, order patterns, and internal distances, while scenarios simulate productivity and capacity impacts before physical changes are executed.

Use cases: layout optimization, picking route optimization, location assignment.

Typical impact: higher lines per hour, shorter travel distances, and improved picking accuracy and lead times.

Orders, materials, real line capacity, and setup times are combined to continuously resequence production and anticipate bottlenecks, preventing variability from turning into execution failures.

Use cases: intelligent sequencing, constraint detection, short-term plan adjustments.

Typical impact: improved OEE, higher plan adherence, and reduced downtime and changeovers.

Energy consumption is analyzed as an operational pattern, identifying inefficiencies and recommending parameter adjustments that reduce energy usage without compromising throughput.

Use cases: inefficiency detection, recommended setpoints, assisted control.

Typical impact: lower kWh per unit, reduced unit cost, and progress toward sustainability targets.

Micro-stoppages, station imbalances, and cycle variability are translated into root-cause diagnostics and concrete actions, flow redesign, workload redistribution, and process stabilization.

Use cases: loss analytics, line balancing, operational recommendations.

Typical impact: higher productivity, improved process stability, and reduced scrap and rework.

Operational signals and images detect deviations and defects before they result in rejected batches, enabling assisted or automated corrective actions based on criticality.

Use cases: anomaly detection, quality inspection analytics, real-time alerts.

Typical impact: higher FPY, lower PPM, and reduced cost of poor quality.

Vibration, temperature, sound, and energy consumption become predictors of asset health, estimating optimal intervention timing to minimize downtime and extend asset life.

Use cases: failure prediction, work-order prioritization, condition-based maintenance.

Typical impact: reduced downtime, improved MTBF/MTTR, and lower corrective maintenance costs.

Orders, delivery windows, capacity, traffic, and weather continuously feed route and priority re-optimization to meet commercial commitments at lower operating cost.

Use cases: dynamic routing, load reallocation, window-based prioritization.

Typical impact: improved OTIF, lower cost per delivery, and fewer unproductive kilometers.

An analytics-enabled control tower integrates telemetry, traffic, inventory, and operational status to anticipate incidents and orchestrate responses before disruptions escalate.

Use cases: predictive ETA, alerts, automated or assisted contingency responses.

Typical impact: higher service reliability, fewer disruptions, and more accurate ETAs.

Behavior, preferences, and context are translated into actionable clusters that increase the relevance of offers, propositions, and experiences at scale.

Use cases: clustering, propensity models, consumption drivers, actionable profiles.

Typical impact: higher conversion and uplift, improved CAC/ROAS, and category growth.

Audiences, messages, sequencing, and channel mix are optimized based on performance and saturation, aligning marketing execution with sales and supply constraints.

Use cases: mix optimization, budget allocation, demand–supply coordination.

Typical impact: improved ROI/ROAS and more consistent execution.

Digital conversations and signals are converted into actionable insights on brand attributes, reputational risks, and emotional drivers that influence portfolio and communication decisions.

Use cases: advanced social listening, early risk detection, sentiment and topic analysis.

Typical impact: improved share of voice and sentiment, faster reaction to external events.

Omnichannel integration enables a deeper understanding of value, sensitivity, and lifecycle stage, activating loyalty, pricing, and portfolio strategies with greater precision.

Use cases: customer 360, next-best-offer, journey analytics, LTV modeling.

Typical impact: higher retention, improved LTV, and gains in NPS/CSAT.

Elasticity, competition, costs, inventory, and demand are combined to recommend optimal prices by SKU and channel, with more frequent and controlled adjustments that capture value without eroding competitiveness.

Use cases: price optimization, channel-specific rules, scenario simulation.

Typical impact: incremental margin, improved realized price, and higher rotation and share.

Promotions are evaluated based on true value, incrementality, cannibalization, return, and sensitivity, redirecting investment toward mechanics and customers that generate measurable impact.

Use cases: incrementality measurement, investment optimization, channel-level recommendations.

Typical impact: higher promotional ROI and reduced inefficient spending.

Pricing, promotions, portfolio, and channel decisions are modeled jointly to maximize profitable growth, aligning commercial strategy with logistics and operational constraints.

Use cases: multivariable optimization, scenario analysis, mix recommendations.

Typical impact: net margin improvement, profitable growth, and cross-functional alignment.

Historical data, behavior, and interaction signals guide recommendations for the next best offer, message, and commercial sequence at the customer level.

Use cases: propensity models, recommenders, account prioritization, assisted playbooks.

Typical impact: higher conversion and win rate, improved sales productivity.

Purchase behavior, complaints, and sensitivity indicators anticipate churn risk and proactively trigger retention actions.

Use cases: churn prediction, retention offers, customer prioritization.

Typical impact: lower churn and improved retention and LTV.

Complaints move beyond case-by-case handling to root-cause analysis, enabling structural improvements prioritized across functions.

Use cases: topic modeling, causal analysis, initiative prioritization.

Typical impact: improved CSAT/NPS, lower recurrence, and faster resolution times.

Financial modeling and advanced analytics calculate true cost by customer, channel, and service level, enabling explicit trade-offs in commercial and operational design.

Use cases: granular profitability, service-level optimization, commercial condition redesign.

Typical impact: higher net margin, reduced cost-to-serve, and faster decision-making.

Across the value chain, AI enables organizations to read operations with greater depth and respond with greater precision.

When data, processes, and decisions are integrated within a single system, friction becomes visible, efficiencies are captured, and results are sustained over time. In consumer markets, this is already enabling a more connected, measurable, and value-oriented way of operating.

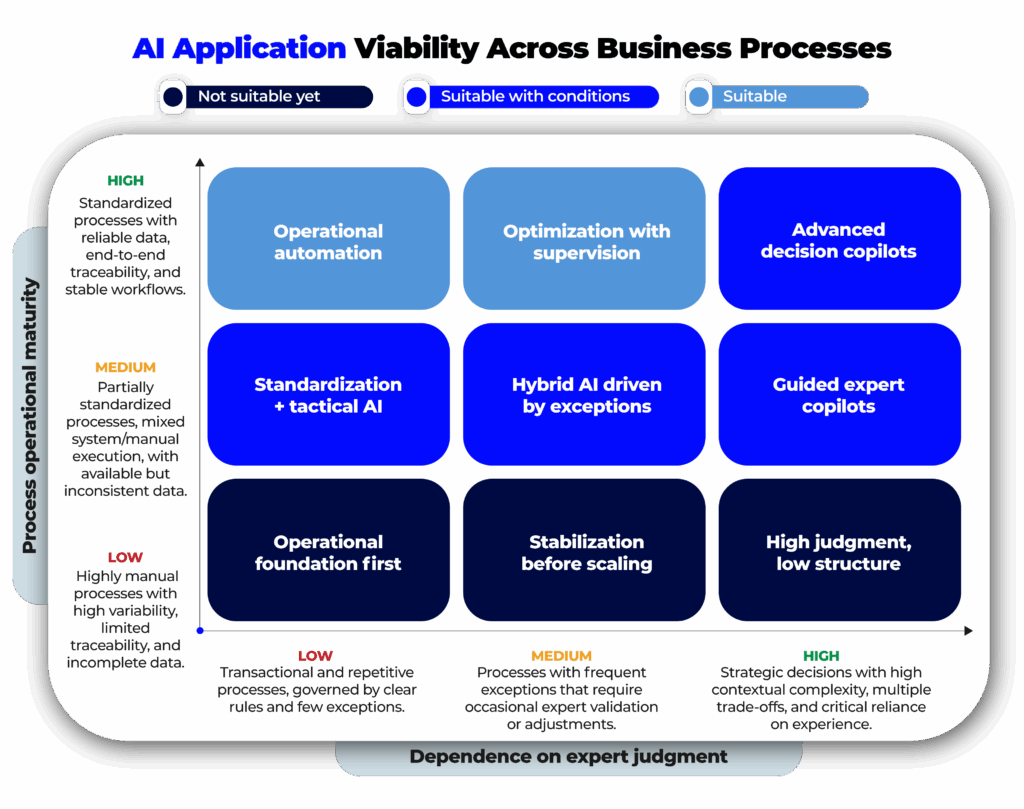

The challenge is understanding where AI creates value and under which conditions. Each use case requires a different level of standardization, automation, and expertise; knowing the starting point helps distinguish quick wins from initiatives that require first strengthening the operational foundation.

To support this, we developed a readiness matrix that evaluates each process by operational maturity and dependence on expert judgment, guiding use-case prioritization and the construction of a roadmap toward operational or advanced AI.

Stable, repetitive processes governed by clear rules, where AI can automate allocations, sequencing, replenishment, or prioritization with a high level of accuracy.

AI proposes adjustments, identifies exceptions, and optimizes decisions, while teams intervene only to validate atypical cases or address specific variations.

Models that support strategic decisions through scenarios, simulations, and recommendations require traceability, governance, and validation criteria to ensure reliability over time.

Use cases focused on quick wins such as tactical forecasting, inventory rules, prioritization, and alerts. Sustained impact requires data cleansing and closing operational gaps.

AI learns patterns and suggests actions, but requires frequent expert interaction to interpret scenarios, adjust recommendations, and correct deviations.

AI accelerates analysis, compares alternatives, and enhances expert judgment in processes where meaningful variability still exists. Best suited for controlled pilots and narrowly scoped use cases.

Before enabling AI, processes must be structured, records digitized, workflows standardized, and minimum traceability ensured so models can learn consistently.

With inconsistent data and variable processes, AI amplifies errors rather than value. The priority is to stabilize operations, strengthen discipline, and build reliable performance indicators.

Processes dominated by expert judgment but with limited documentation and low data quality. Structure, metrics, and information governance must be consolidated before introducing safe AI copilots.

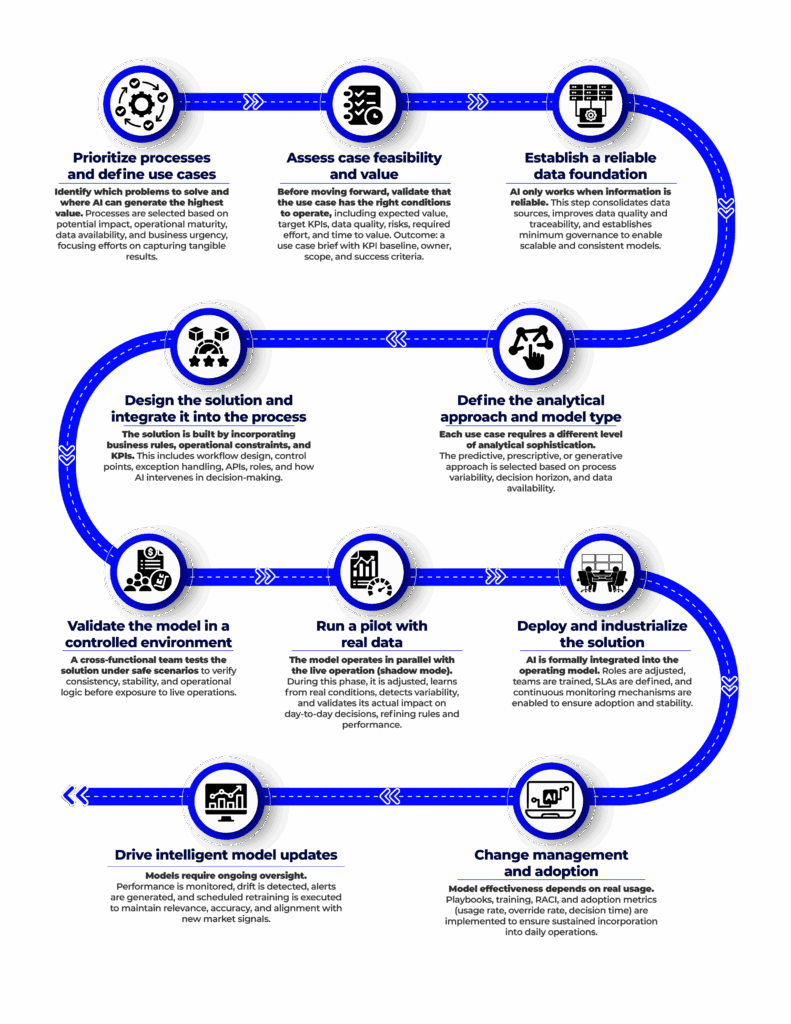

Advancing AI adoption requires a clear, structured path focused on priority processes. Successful implementation combines technical, operational, and organizational elements to ensure consistency, learning, and scalability.

Below is an implementation framework applicable across any stage of the value chain:

AI integration across the value chain is a capability that is built and refined over time. Its impact materializes when processes are well defined, data is consistent, and the organization can convert information into actionable decisions.

At that point, AI evolves from a technology initiative into a strategic enabler, strengthening commercial discipline, improving efficiency, and expanding the organization’s ability to navigate market volatility. In the consumer industry, this approach supports clearer execution, more precise responses, and sustained performance as market dynamics continue to shift.