Increase in service level with new picking tunnels and expanded storage capacity

Reduction in traffic volume along the plant’s main axis

Reduction in raw material losses due to internal layout adjustments

The company, a leader in the consumer goods industry in Brazil, faced the challenge of optimizing the internal logistics of its plant, especially with space expansion and the lack of a circular internal flow. Partnering with Sintec Consulting, they implemented innovative solutions, such as new picking tunnels and expanded storage capacity, significantly increasing service levels. The redesign also led to a reduction in traffic volume along the plant’s main axis and minimized raw material losses through internal layout adjustments. These improvements resulted in greater operational efficiency and enhanced overall plant performance.

“Struggling with space expansion and inconsistent internal logistics flows, the company faced major operational inefficiencies”.

The company faced significant challenges in optimizing its internal logistics, especially regarding the anticipation of investment for space expansion and the inability to establish a circular internal logistics flow. Additionally, excessive variability in receiving and shipping operations further complicated the situation. These issues hindered the company’s ability to streamline processes and maintain efficient operations across the plant.

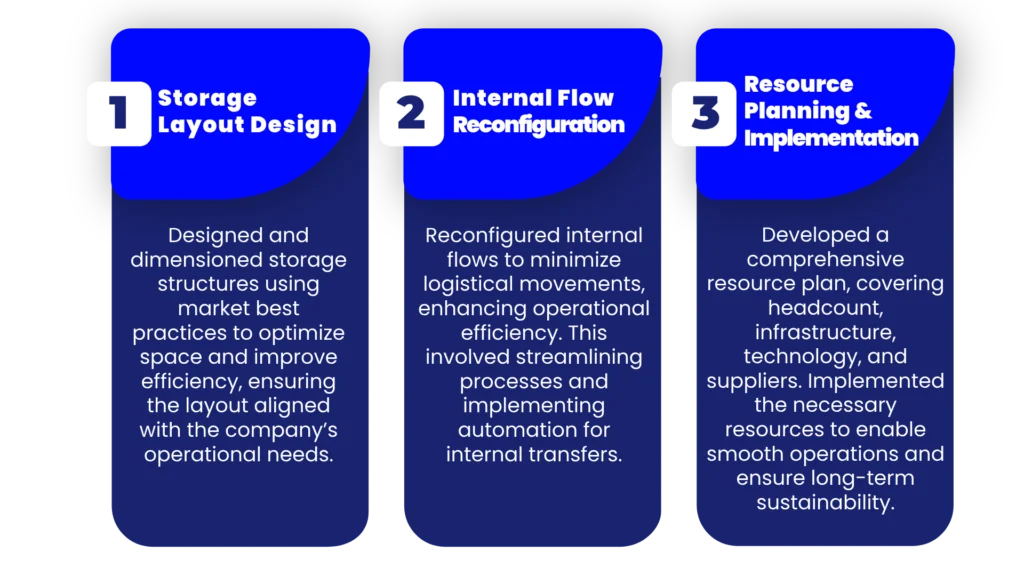

The company partnered with Sintec Consulting to optimize its internal logistics and improve operational efficiency. Sintec Consulting’s tailored approach helped address space expansion issues, streamline flows, and implement advanced technologies.

The project yielded highly impactful results, driving operational efficiency across key areas. Notably, service levels increased by 10% through new picking tunnels and expanded storage capacity. Traffic volume along the main plant axis was reduced by 30%, and raw material losses decreased by 13% due to internal layout adjustments. These improvements not only optimized internal processes but also enhanced overall operational performance, positioning the company for continued growth and success.

This is a brief summary of the case. If you’d like more details or want to learn how our solutions can help your business, feel free to reach out through our contact form.