Improved demand planning accuracy with advanced forecasting models.

Enhanced inventory management and cost control across the supply chain.

Optimized production and distribution for faster, more efficient operations.

A leading food industry company in Chile, renowned for its solid presence in national and international markets, faced challenges with fragmented tools and processes that were hampering informed decision-making and operational efficiency. Through collaboration with Sintec Consulting, they implemented SAP IBP (Integrated Business Planning) to optimize supply chain planning, enhancing accuracy, efficiency, and market responsiveness. This transformation further strengthened their leadership position in the Chilean food industry.

“Fragmented tools and poor visibility stifled decision-making and operational agility.”

The company encountered significant challenges in supply chain management due to fragmented tools and processes. This fragmentation hindered their ability to make timely and data-driven decisions. Limited real-time visibility and insufficient cross-departmental collaboration impacted operational efficiency, compromising their ability to respond swiftly to market dynamics and demand fluctuations.

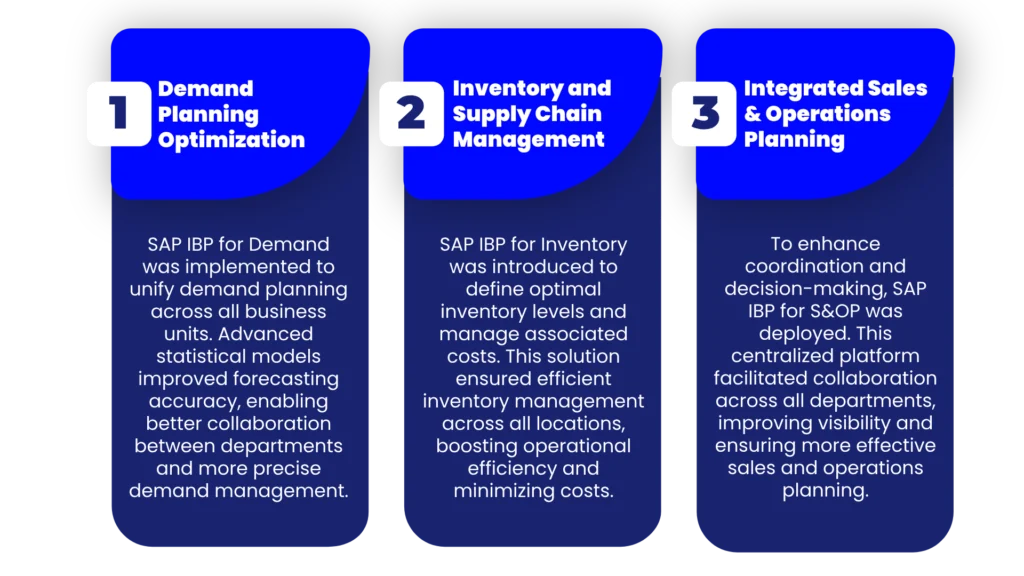

The company collaborated with Sintec Consulting to transform their fragmented supply chain processes and tools. Leveraging Sintec’s expertise, they implemented SAP IBP to optimize demand planning, boost operational efficiency, and enhance market responsiveness. This comprehensive solution streamlined end-to-end supply chain operations.

The implementation of SAP IBP delivered transformative results across the company’s supply chain operations. Enhanced demand planning accuracy drove significant improvements in inventory management and cost optimization. Increased agility in responding to market dynamics substantially elevated customer satisfaction levels. The streamlined integration of production, distribution, and sourcing processes led to reduced cycle times and optimized resource utilization. These achievements have established the company as a benchmark in supply chain excellence within Chile, creating sustainable competitive advantages in the market.

This is a brief summary of the case. If you’d like more details or want to learn how our solutions can help your business, feel free to reach out through our contact form.