Increased productivity of distribution center

Roadmap of initiatives and recommendations for effective warehouse operations

A leading grocery distribution company in Mexico partnered with Sintec Consulting to design the layout of a new distribution center, addressing operational challenges from previous designs. The initiative aimed to break through the limitations of existing practices, transforming the distribution processes by optimizing inventory management, improving the flow of goods, and ensuring future scalability. This revolutionary vision streamlined operations, boosting productivity and establishing a more efficient foundation for long-term growth.

“Outdated layout and bottlenecks in shipping, storage, and loading demanded a redesign to meet evolving needs“.

Facing critical operational constraints, the company was compelled to overhaul an outdated layout that no longer met its evolving business needs. The absence of dedicated zones for shipping and receiving resulted in persistent bottlenecks, while limited pre-assembly and pre-shipping spaces further hindered efficiency initiatives such as optimizing truck loading. In addition, the storage area was misaligned with target inventory levels and lacked the flexibility to adjust to fluctuations driven by supplier negotiations or seasonal demand variations. The shortage of parking for night shift pre-loading compounded these issues, collectively jeopardizing the smooth flow of operations and demanding an innovative, comprehensive solution.

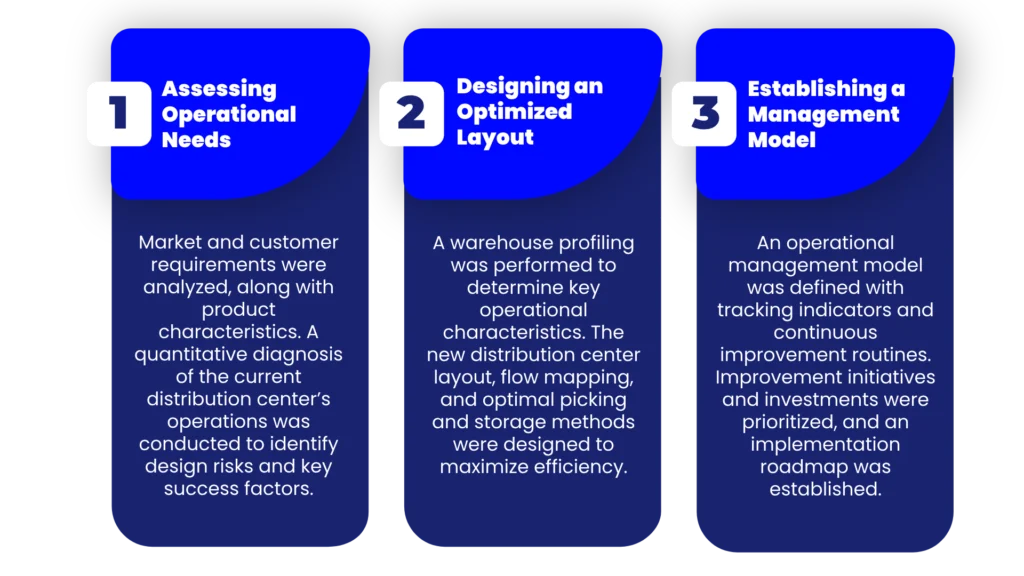

The company partnered with Sintec Consulting to design an optimized layout for its new distribution center. This initiative aimed to enhance operational efficiency, reduce bottlenecks, and align warehouse processes with business needs, ensuring scalability and long-term performance.

The project delivered significant results, driving a 25% increase in productivity and optimizing warehouse operations. A structured roadmap of initiatives and targeted recommendations ensured the effective operation of the new distribution center. The optimized layout design, streamlined picking and storage methods, and enhanced management model improved decision-making and operational efficiency. Additionally, the defined monitoring indicators and continuous improvement routines enabled long-term scalability, ensuring flexibility to adapt to inventory fluctuations and business growth.

This is a brief summary of the case. If you’d like more details or want to learn how our solutions can help your business, feel free to reach out through our contact form.