The Supply Chain relates to the companies that comprise it from the beginning (unprocessed raw materials) until the arrival at the final consumer, therefore decision-making is vital to their success.

In the case of logistics companies, transport operations may be functioning properly (apparently), but the reality is that: if you are not measuring, then you cannot be sure.

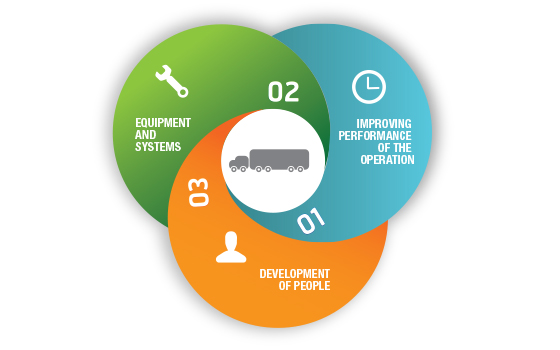

Transport consists of: operation, equipment and systems and people. Understanding and monitoring the performance of each element is a major challenge due to the complexity of the Supply Chain. A first step is the collection of data on the most important aspects of the process and its processing in specific performance indicators. We must take into account that the indicators must be significant to your operation, as well as specific, measurable, attainable, realistic and timely.

In relation to transport, there should be a focus on the key components of the operation: Cost, Operation, Service, Implementation and Maintenance.

How to measure the transportation performance in your organization?

Below are the steps for measuring the effective performance of the logistics area:

- Select the performance indicators: Before deciding which indicators to use first, it is necessary to decide what you want to know about the operation.

- Define and review goals: The most important point is to align the strategic goals to the organization.

- Data collection: Once the sources of information are identified, such as: manuals, automatic collection and specific systems, they are integrated into existing management systems.

- Review and Evaluation: The frequencies should be stipulated, as well as comparisons based on an internal and external benchmark.

- Publication and feedback: The form in which performance information is displayed can make a big difference in the success of its management. It should normally be graphical and include the measurement of the current situation against the previously defined objective.

- Identify the strategy for improving performance: Once the indicator with low performance is identified, the improvement strategies are defined, such as: training, sharing best practices, seeking reasons for poor performance, etc.

- Execute the actions for implementing the strategy: Once the strategy is identified, activities are defined which are aimed at improving performance, therefore, it is necessary to assign dates and a person in charge of tracking and monitoring results.

Operation, Equipment/Systems and People

Efficiency of the operation

Routing: Using software for route planning and optimization allows for reducing travel time and mileage, planning the most effective route, maximizing the efficiency of deliveries and reducing the number of trips and vehicles required.

Vehicle use: This recommendation is a direct means of reducing costs by making more efficient use of vehicles and the use of operators. One way of doing this is through the use of equipment that makes return trips with third-party or own loads.

Warehouse operations: Warehouse operation directly affects transport and fleet operation. The measurement of performance according to internal service levels allows for distribution and the transport process to not be affected.

Internal communication: The processing of orders and the sales department can have a large impact on the efficiency of the transport operation. In this case, the impartial performance indicators between the two areas can reduce errors such as: repeat deliveries or reduce late deliveries due to processing outside the agreed time; as well as the reduction in the number of orders expedited due to lack of clarity of the delivery requirements.

For handling orders, the PRM system (Partner Relationship Management) can interact directly with the customer’s inventory system (Distributor) where, under predefined criteria and policies, it is possible to place orders automatically or manually, supporting inventory strategies throughout the chain.

Operator training: Changing the means of driving in terms of style and technique can be the activity with the greatest impact in relation to fuel savings. This type of training includes topics such as: route planning, cargo and height position, weather, tires, braking, etc.

There are cases where 13% reductions in fuel consumption have been achieved four weeks after training.

Data collection and fuel savers: These indicators and systems allow for collecting information in the equipment or from places where fuel is loaded. They can be manual measurements whenever fuel is supplied to the equipment, as well as digital measurements with the use of cards or chips.

2. Equipment and systems

All transport operations are based on the performance of a wide variety of equipment. Therefore, it is important to understand how each piece of equipment is used in the operation and if the equipment is suitable for the operation.

Fleet innovation: Comparing the performance by means of standard indicators of different types of vehicles provides support to the basis for improving future purchases; factors such as: maximum permissible weight, size, engine, torque and design are just a few of the factors that should be checked. Part of this concept is to be innovative through the use of new types of equipment, such as double-decker (widely used in Argentina) or detachable trailers.

Fleet condition: This factor affects both the effectiveness of the operation and fuel consumption. It should be evaluated when it is time to renew part of the fleet in such a way that the average age of the equipment allows for more efficient operation.

Aerodynamic style: Some accessories help to reduce fuel consumption. It is necessary to evaluate cost versus savings. One option is to use two equal vehicles, adding the accessories only to one, comparing them using the same indicators and waiting for results.

Tires: Reduction of the tire resistance can have an impact of up to 5% of fuel consumption.

3. Development of people

Your employees are your main asset and play a vital role in distribution and transportation services. Investing in training and development supports the adoption of technological change and retention of staff; this latter point is a significant problem in the transportation industry.

Training of operating personnel

- Skills: driving, computer skills, maintenance, etc.

- Personal skills: customer service, teamwork, etc.

- Knowledge: vehicle, hazardous materials, legislation, etc.

Administration and Management

For the administration and management personnel, it is also necessary to have technical and personal knowledge and ability; however, they vary from those defined for operators.

- Technical capabilities: Computing, finance and performance management.

- Personal skills: Team work, customer service, commercial.

- Knowledge: Transportation policies, customer priorities, legislation.

Conclusions

Measuring performance can take time, but it’s worth it if it improves your operating performance and efficiency. The starting point of any performance measurement system is the understanding of the strengths and weaknesses of the operation.

Weekly or monthly reports and graphical presentations of performance results support highlighting areas of opportunity for the operation.

Understanding and monitoring performance of the organization is a challenging process, and performance measurement is essential before defining rules to improve operational efficiency and reduce costs.