Nowadays we are hearing several questions from our clients on how to improve operational efficiency, as a way to guarantee profitability of the companies in these times of economic crisis. Generally that question comes with an interest in making the operation stand out as a competitive differential in customer service in several sectors or industries.

In this uncertain context, what are the alternatives available for an executive to improve efficiency? How to understand and carry out the necessary changes to improve satisfaction and to reduce costs, with scant resources, which are often needed for efficiency leaps? In the recent past, the search for competitiveness involved the renegotiation of contracts, the outsourcing of services, the automation of the production or simply the gathering of functions and the reduction of the workforce. Today there are less and less alternatives to develop new projects and there is only a few areas that haven’t been gone through innovation reviews or processes.

In this scenario we see a real need to improve the order management process, and the Commercial area stands out as a protagonist of the change.

THE COMMERCIAL AREA:

The demand of results will always be the main requirement from the commercial area, but its participation in the rest of the process has become crucial for the organizations, as it is this area that kick starts the chain when it indicates the demands, requests and requirements of its clients.

Among our clients we see different levels of maturity in the execution of the way orders are recorded. We work with companies that barely have a clear understanding of delivery times, of the internal lead time and the availability of products (it seems strange, however there are still large companies that act without a basic understanding of the operation) all the way up to organizations that have a greater development, where systems offer a breakdown of what is being ordered and demand is managed and linked to production.

In any of those cases, we see that generally there is an absence of clear rules and defined processes that assist the hardworking commercial area in filling the “perfect order”.

THE “PERFECT ORDER”

Many organizations are already discussing the perfect order, but the concept continues to raise many questions and to generate apprehension in executive boards and among management. The standard description is an order that is delivered at the right place, on the right day, to the right person, in the correct amounts and in flawless conditions.

But, we can see in practice that this classification fails in guaranteeing an optimal cost of delivery, item availability, minimum delivery times and the ability of the operation and any available resources to make the delivery in accordance with the definition.

In Sintec projects, we have found companies that have order management systems in place, but their systemic processes and rules are scantly developed and inadequate to achieve better results. In addition, we rarely see accountability for problems derived from a poor implementation of the orders, and an adequate prioritization to improve it.

The impacts of the lack of balance of business parameters and processes are many, and they affect the entire organization, from the commercial area itself, which has to deal with several cancelations and the duplication of orders, to the operational area, which faces high ratios of inventory shortages and management complexities, to the delivery area, which is affected by the lack of products, and by late deliveries, and redeliveries that directly incur in costs.

In service companies, problems are not different. Technicians return to the clients many times due to schedule problems, lack of information and technical queries, and it takes them days to complete simple installation or maintenance services.

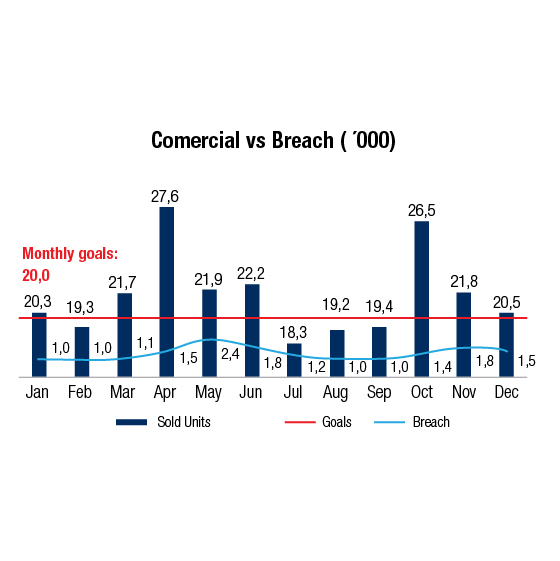

Based in recent history, we present 2 real situations that were experienced by large clients who are leaders in their segment, with operations that move tens of third parties and service providers, hundreds of clients and thousands of orders per month.

CASE STUDY 1

The initial scope of the project was to make a detailed assessment of the inventory and its imbalances. At the start of the diagnosis, we saw signs of a strong unbalance of demand, impacting the entire operation. After weighing the participation of seasonality in the results and dismissing its effects in the analysis, we concluded that there was a strong correlation between the demand of some products and several impacts on the stock, cancellations and delivery delays.

Then we studied the main factors of the imbalance, and reviewed the processes throughout the chain, monitoring occurrences at every stage. After completing the diagnosis, first it became necessary to raise awareness in the company with regard to the problems derived from a poor management of the orders, and then we started the necessary adjustments to order management rules and procedures.

In cases such as this one, reviewing the process is only a part of the change, because the bigger complexity is in the cultural change and in earning the support of the executives we lead in our projects.

The order and service management process requires a structured process, which takes into consideration the segmentation of the demand, followed by the definition of service rules and parameters, based on the service offering of each channel or group of clients. It is only after completing this process that any changes to the system and any new procedures must be designed, based on the characteristics of the business and the goals of the corporation.

CASE STUDY 2

The second case analyzed was that of a Brazilian multinational, leader in its sectors, which hired Sintec to increase its shipping efficiency. During the project, the team was divided in 3, including a group in charge of reviewing internal processes. Despite the fact that the original focus was to reduce costs, the inconsistencies we found in the recording of orders and its impacts in the delivery operation required a thorough understanding of the process.

The operation was extremely dynamic, with sales normally marked for immediate delivery. In this process we discovered the fact that no indicators existed to calculate the correct completion of the deliveries, or even a chance to develop them, since many of the dates that the clients were asking were before the date of the order, (in other words, many orders were recorded as already being behind schedule!!) and in other cases there was barely a consideration of the time needed to complete internal procedures, such as separation and transit time.

In addition to the serious problem with the recording of the dates, no standard procedure existed to record orders exceeding the capacity of a vehicle, or orders with more than one delivery date. It was common to find a single order and a single delivery date for the entire monthly volume requested by the client. Last, orders were segregated sequentially, incurring in several deliveries and in an inefficient operation.

This way, in addition to the evaluation of the potential for cost reductions for the client, making critical adjustments to the operation became an important part of the deliverables of the project.

SINTEC METHODOLOGY

These cases exemplify the many problems derived from order registration practices that can be faced on a day to day basis. Although the (commercial, operation and logistics) areas are interdependent, they are normally treated individually, without a holistic vision that guarantees consistency in their activities.

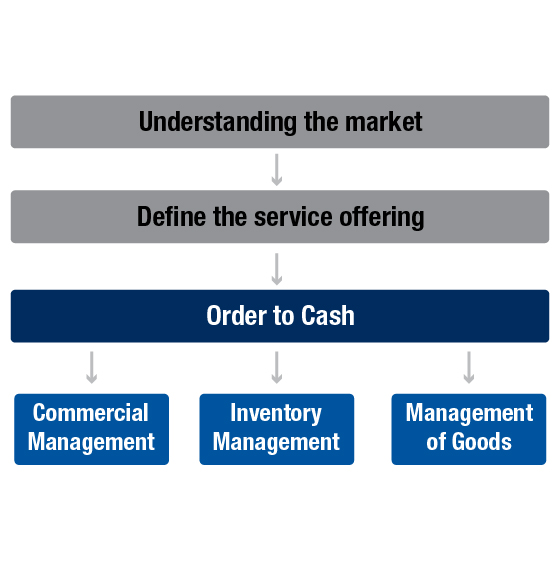

The integration of the internal processes starts with a detailed understanding of the market / customers, their requirements and needs. This study facilitates the assessment of the potential benefits of order management and the definition of the way the company is to differentiate itself from its competitors. Then, it will be necessary to analyze the segmentation of the customer base to breakdown the service offering based on the different needs and characteristics of each group, such as their lead times, service levels, the frequency of the reviews, among other factors that will serve as the basis to structure the service channels and the service offerings.

Only after completing these phases can the Order to cash (OTC) process be structured to solve any difficulties experienced, like the ones we saw in the above cases, and to define the parameters that shall govern the operation.

The realization of the Order to cash facilitates the design of an internal structure and procedures that are in line with the external requirements of the market, and the internal complexities of the operation, guaranteeing a more efficient performance of the operation.

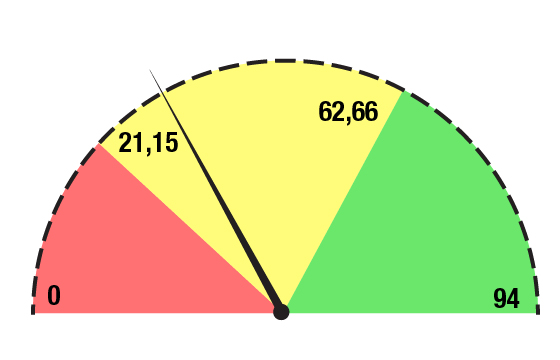

This process takes place throughout, essentially the following phases: the identification of the opportunities in the Order to delivery OTD process, the redesign of the new Order to cash model, the definition of KPIs, the definition of operational routines, the definition of IT requirements, the preparation of the business case all the way to its implementation.

CONCLUSION

For the reduction of the costs of an operation to be perpetuated, it is indispensable to adjust the internal activities. This process, not only guarantees an increased efficiency, but it also offers more long term opportunities for its evolution.

Past projects show that the first results take 4 to 8 months after the start of the activities to appear, but they also confirm that the new thresholds remain stable in the mid and long term, with a structure that is capable of supporting the increase of the volume, without any need to make expenditures in the same proportion.

At times when there is pressure on the business margin, acting punctually in the reduction of the workforce or the slashing of the budget is not enough. We know that operations, and the impacts of business decisions, are interdepartmental, so to achieve long lasting results it is imperative to act integrally, over the entire chain, from the arrival of the order to the final delivery.