It is common for a CEO to have an impeccably defined business strategy, while at the same time having doubts about how to ensure its proper implementation. One lever for achieving it is a clearly defined and aligned Operations Strategy.

We often hear how companies with rapid growth often want to perpetuate the modus operandi that led up to that point, without accepting that this is not enough for achieving stability and supporting the next challenges that the pace of business will give rise to. By not evolving, this type of companies tend to focus its operation on solving problems of today, without a solid basis which sees beyond the immediate, resulting in inconsistencies, poor service, high costs, misalignment with the commercial area and becoming an obstacle to the strategy and profitable growth.

This was the situation of our client, a company in the consumer market in Mexico, with a history dating back more than 65 years of success and tradition, but with solutions that were not on par with the growth and demand of its customers. The main problem arose because, in the face of the evolution of the business, there was no clear alignment between the operational and commercial strategy. The operation then fell on the shoulders of individuals who tried at all costs try to solve urgent problems, without considering the implications that short-term decisions would have in the medium and long term.

So, what can a company do with a rapid expansion but a nearsighted operational vision for achieving its profitable growth goals?

This document shows the success story of our client, positioned as a leader in its industry in the Mexican market, for which a Sintec multidisciplinary team designed and implemented a comprehensive solution tailored to its needs.

Complexity in 4 Years: When Growth is a Problem

Our client was facing complexity and the significant challenges that rapid growth had brought in just 4 years: +52% products, + 70% of volume, +83% of positions in warehouse, +53% production lines.

Its market chains included the modern channel (supermarkets and convenience stores) with high service demand, as well as some large distributors to the traditional channel (corner shops and stands). The operation included 2 plants, where more than 500 products were produced, with shelf lives ranging from weeks to several months, and 3 warehouses that supplied the whole country.

Because of this growth, the lack of an appropriate operations strategy became a constant headache and an obstacle to the execution of the business strategy.

Understanding the Operation

The project had a first phase for obtaining a good understanding of the operation and its areas of opportunity. We interviewed 62 participants from the different business processes and analysis was performed of cycle time, service and cost for Transport, Production, Inventory, Order Processing and Forecasting.

The main points to attack and which defined the design guidelines were:

- Lack of clearly defined Service Offering for different customer groups. The service provided, in general, was the same for all customers, but with monthly changes in service levels, and relied on short-term priorities, without defined rules for prioritizing when there were supply problems.

- Misalignment between the commercial area and the operation. The priorities defined with customers were not clearly communicated for their execution and, even worse, service commitments were made without knowing if they could be met.

- Misaligned supply strategy. The products were produced, inventoried and moved according to a forecast with a high level of error and a generated from a poor process.

- Inconsistent and inefficient processes. In light of changing priorities, operational processes were executed differently and decisions were routinely made with incomplete information, all under the banner of complying with the order attended to at that time.

- Lack of process management. There were not suitable indicators generated and monitored with appropriate frequency.

- A comprehensive organizational structure. Certain relevant decisions of the operation had no clear responsibility; furthermore, some resources did not meet the profile required for the position.

- Lack of technological enablers to adequately support the processes.

The result was a service below that expected by customers, with high costs and a direct impact on the profitability of the business in two ways: The poor service lead to lost sales and the high costs further decreased profitability. As a result, it was a service below that expected by customers, with high costs and a direct impact on the profitability of the business in two ways. The poor service lead to lost sales and the high costs reduced profitability even more.

Solution for Medium and Long Term

The solution to this problem departs from grouping clients served based on common characteristics (segmenting); defining-based on business priorities-a service commitment with each group; and, taking this as a basis, understanding the implications of the supply chain to ensure that it can meet these commitments.

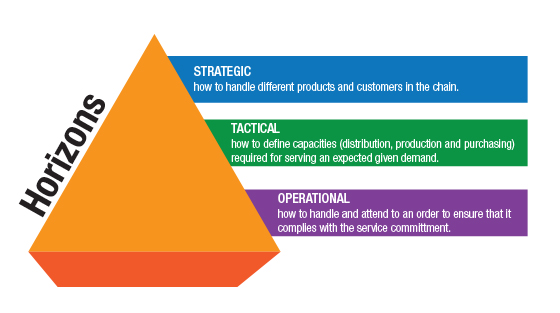

The following table shows 3 horizons of decisions to consider in changes to the chain:

What are required for maintaining rapid growth are formal, robust, consistent and repeatable processes which allow for making decisions to balance the business priorities between short and long term, and it is also vital to have appropriate organizational and technological enablers for the value chain. Taking this into consideration, the solution designed and implemented in the consumer company focused on the following points:

- Customer Segmentation and Offer of Differentiated Service.It was done to classify customers with common features into different groups based on Sales, Profitability, Potential and elements of the Service Cost. In terms of the benefit generated to the business, different service offerings were defined, including priorities of service, flexibility in care, committed service and portfolio.

- Defining a Differentiated Supply Strategy. Products are grouped based on the behavior of their demand and different ways are defined for handling and planning the products based on their group: forecast, inventory, etc.

- Process Redesign for Tactical and Operational Planning. Processes of Sales and Operations Planning (S&OP), Portfolio Management, Demand Planning, Distribution Planning, Production Planning, Transportation Planning, Purchase Planning and Order to Deliver.

New processes considered new definitions of service commitments, forms of treatment for different products, and also defined a “should be” and, from there, other necessary enablers were defined. - Definition of Organizational Structure for the Supply Chain. The distribution of responsibilities and decision-making were redefined to ensure the balance between service and cost in the operation, the profiles for each relevant position is detailed and all participants (over 70) were evaluated to confirm that they met the required profile, and taking action in cases in which they did not (training, reassignment and, in extreme cases, termination). This included interviews of external candidates for new positions or for which there was no profile internally.

An intensive training program was carried out for all participants of new processes touching the related operational and staff areas (Comptroller, Marketing and Planning). - Definition of technological enablers. The functionalities required of IT tools for supporting the processes were listed. In some cases, for the pilot, simple tools were built that support the startup and more detail than required was given on tools that were built or configured.

- Change Management. An activities plan was defined and implemented which facilitates the adoption of new practices in the company and reduced the resistance to change that may be faced, this included training the management team, communication campaign of progress and achievements, activities monitoring board and business indicators.

- Implementation. Starting on the agreed date, Sintec accompanied the company on all redesigned processes, ensuring the proper implementation and minimizing the impact of the experience curve throughout the organization.

Results: Real Benefits

The company saw the benefits of the solution much earlier than projected, both quantitatively and qualitatively.

Quantitative Benefits:

- Improvement of 18% in service measured by the Fill Rate indicator.

- 4% increase in assertiveness of the Demand Plan.

- Sales growth above 3% as a result of greater availability of product.

- Cost Reduction:

- Reduction of wastage of 3% of sales.

- 81.2% reduction of penalties for breach of service.

- Reduction in secondary transport by 4% due to better capacity utilization of the vehicle

The contribution to profit in the first year was 237% above what was originally planned in the business case.

Qualitative Benefits:

- Improved visibility of business medium and long term.

- Significant improvement of communication between operational and commercial areas.

- Increased understanding of business situations through a higher level of detail in the analysis of processes.

- More specialized teams per process, improved focus and order of the work team.

- Detection of future opportunities for automating manual activities.

Conclusions

The transformation of our customer was based on the reform of its operations. The support and trust of the management team was required and, especially, the effort and participation of the players though the entire Chain. The direction was maintained and detours for unforeseen circumstances and obstacles were removed, setbacks were learned from and, finally, a great business result was obtained which is today a source of pride for its protagonists.

By absorbing and sustaining change, the operation grew from a concern for the CEO to an enabler of growth and strategy execution. Today, the COO balances his time between short-term and longer term decisions that will allow the operation to continue to be an enabler of strategy.