WHAT IS THE CONTEXT OF THE BUSINESS?

The company in our analysis imports, manufactures, markets and distributes medicines and personal care products within its network comprised of more than 400 pharmacies of the retail channel and sales to distributors. Its network in 2013 was made up 1 plant, 6 distribution centers and more than 180 national and international suppliers.

It had two main sales channels, the channel retail with the pharmacies or drugstores representing 83% of sales and a distribution channel for drugs that had the remaining 17% of sales, with a lower contribution margin.

Its turnover is over $270 million dollars and it belongs to the top 10 of the largest companies in the chemical and pharmaceutical sector of a country in the Andean Region. Its network of pharmacies serves the country both in both cities and in very remote and inaccessible areas, where it is often the only presence.

In 2011, it implemented an ERP and a module for demand planning; however, it is acknowledged that during this implementation, there was a lack of alignment of processes and organizational readiness for the changes to the new technology. It was thought that the automation of manual processes and multiple statistical forecasting models would be sufficient to improve business performance.

WHAT LED THE COMPANY TO BE IN THE RED AND ILLIQUIDITY?

The implementation accelerated problems in the processes and the organization because wrong decisions were automated. This situation led the organization to lose value in an accelerated manner; for example, decisions associated with parameters and configuration of the technology led to accumulation of inventories in warehouses and retail outlets, in addition to the effect on service levels.

Before our arrival, the company was working on three fronts to improve performance:

- Increase participation in the retail channel and improve the level of service through increased inventory levels at retail outlets.

- Construction of a new distribution center that would consolidate the operation of the other warehouses and would allow for reducing the overall inventory.

- Improve the use of tools to increase the certainty of the prognosis and make purchases further aligned to demand.

The initial situation could be described with the following symptoms: more unnecessary purchases, bad product placement in retail outlets, increased global inventory and lastly, more financial problems; as a result it generated an outright destruction of value. After a short period of analysis and diagnosis of the processes, the following opportunities were identified:

- The purchasing planning process was carried out with partial inventory information and the system had isolated the stock of pharmacies. Often the purchases were made according to average consumption, using intuition of the buyers or being influenced by vendor offers.

- The inventory policies were calculated for pharmacies monthly, but their calculation did not consider the variability of the products in retail outlets. Additionally, they had an ABC classification which was inadequate for focusing efforts.

- There was low reliability of inventories in branches and pharmacies.

- The newly opened Central Distribution Center had very low levels of service even when it had high availability of products. There were errors in the supply of orders, or picking, and in addition to this, the lack of capacity to respond to the daily replenishment orders made it so that only 50% of what was requested was dispatched within 24 hours.

- There was a monthly demand plan with low participation of commercial areas. In addition, the indicators did not allow for assessing the reliability of the forecast and the effects of collaboration because it was not performed entirely within the system, a situation which did not allow for generating the expected visibility for the organization.

- High recrimination and mistrust between areas were problems associated with inventory, shortages and out-of-stock. The atmosphere was confrontational and there was a search for culprits in the internal meetings.

THESE ERRORS CAUSED IN THE BUSINESS:

- Imbalance (excesses and shortages) of inventory in retail outlets.

- Impact on service at retail outlets, lost sales and customers in the Distributors channel who, although they generated their estimated sales, did not have availability of product to meet expected that demand.

- Lack of cash flow to pay suppliers, which expanded the problem of service of products that did have rotation and needed replacement.

- High working capital with high bank financing, capital contribution of partners and some suppliers.

In short, the organization did not have the competencies and capabilities to execute the strategic guidelines proposed, which led it to suffer negative impacts on sales, costs, expenses and investments, and thus be in red numbers that required immediate action.

HOW DID IT MANAGE TO CREATE CHANGE?

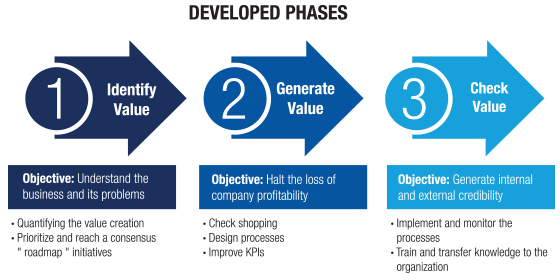

To get the company to start to grow profitably, three phases were carried out in order of priority. For each phase, the corresponding targets and strategies were defined as shown below:

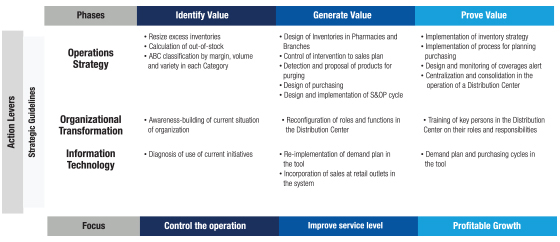

The following figure shows how the strategy was achieved designed to address each of the issues found, focusing on operations strategy, organizational transformation and information technology:

WHAT WERE THE MAIN ACTIONS IMPLEMENTED?

- Design and implementation of a comprehensive planning process supported in a cycle of S&OP (Sales & Operation Planning). This process included meetings, objectives, formats and indicators that promoted the discipline of the organization, allowing for aligning demand, inventories and purchases to a single sales plan.

- Discipline in the organization to maintain the implemented processes and credibility of KPIs.

- Aligning information technology to new processes; improvements were achieved in statistical forecasting, increasing assertiveness by over 18 PP and collaboration in demand was enabled using the planning tool.

- Redesign of product sourcing strategies including segmentation, inventory policy design, implementation plan and training the team.

- Redesign of the Central Distribution Center operations, where designs were made of processes, product layout, indicators, profiles, responsibilities and roles, which allowed operations to align replenishment cycles of pharmacies.

- Consolidation of operations 6-1 without impacting service levels and strengthening the operations of the Central Distribution Center. This allowed for having the pharmacy supply operation in a single distribution center, along with a further reduction in inventory.

WHAT WERE THE RESULTS OF THE ABOVE?

- The fill rate improved by 12 PP and pharmacy orders delivered in the Central Distribution Center within 24 hours improved about 48 PP.

- The availability in retail outlets rose 5 PP, which eventually fell to 3 PP due to the impact of supplier credit.

- This translated into a reduction in inventories and a recovery of capital invested of over $10 million dollars.

The results have been sustainable and improved by the internal business team who were transferred knowledge and were empowered to continue the process and contribute to profitable growth after the accompaniment by the consulting team.

LESSONS FROM THE CASE AND CONCLUSIONS.

- After several months of understanding the business and implementation of these improvements, important lessons were learned which we believe can be summarized as:

- Business processes need to be rethought under a supply strategy. It is not a matter of a redesign (cutting, consolidating or relocating activities), but rethinking how to plan, buy, locate and move inventory for maximum effectiveness for availability of an efficient manner.

- Information technology is a tool that can be used to build or destroy value, the difference lies in having mature processes and a prepared organization.

- The organization can fall into a dynamic of suspicion and recrimination. Changes that integrate processes such as the S&OP and that generate

- value are needed (however small) but that facilitate a more open discussion and problem-solving environment.

Today, they are focused on how to increase the profitability of the retail outlets and how to improve sales through pharmacies by means of optimal

portfolio management. The above problems are not something critical, and the organization has embraced the processes. Now, the challenge is to achieve profitable growth across the business.