At Sintec we develop optimal supply chain strategies that are key to achieving the correct alignment between supply and demand, seeking three principal objectives: increase the customer service level, reduce the cost of service, and optimize the investment in assets in the entire chain and to the market, especially inventories.

Why is it necessary to have a supply chain strategy?

Not having an integrated supply chain strategy can result in business problems like:

- Conflict between different areas of the value chain (commercial vs. operations)

- Loss of profitability

- Lower levels of service

- Inventory imbalance in the chain

- Technology investments without the expected results

- Loss of competitive market response

Sintec Focus

Our solution is based on a an integral strategy design, covering skills, resources, practices, indicators, and information. The solution has two components: Supply chain strategy design and optimal distribution network configuration.

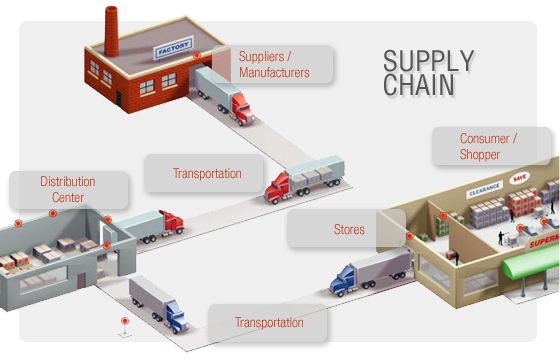

The supply chain strategy that we define along with our client, seeks an optimal allocation of resources (inventories, transportation) and capacities (supplies, production, warehousing, distribution) along the chain. The supply chain processes must be synchronized with these different elements, attempting to comply with the strategic requirements of profitability and service level. The four big supply processes are: purchasing & procurement, transformation, distribution, and delivery.

The supply chain processes must always be subordinate to the value proposition, the market, and to the demand generation processes. They also must operate as close as possible to real time.

Finally, it is essential that the processes are supported by human resources with the capacity to execute them, under an organizational structure that facilitates the coordination and information technology to improve visibility, relation, and decision-making in real time.

Sales and Profit impact at Herdez Group due to new Supply Chain Strategy