Companies are subjected daily to numerous operational risks, and without adequate risk management throughout the supply chain, those negative effects can be significant and long-lasting.

Multinational companies accept that their operations are continuously affected, and although many have mitigation and continuity plans, it is estimated that one in five companies has suffered significant losses due to inadequate response to disruption. In a Georgia Tech study, it was shown that the effects of disruptions in the supply chain can have a significant impact. Based on a sampling of 800 media announcements, typical share price decreased by 8% the day after the announcement. This is worse than the average stock market reaction to other bad corporate news, such as late product launches (5%), financial problems (3-5%), or IT problems (2%). Furthermore, sales as well as profitability were diminished in the two years following a disruption event.

Modern supply chains and operations of leading companies are particularly vulnerable. This is due to various current trends:

- Modern supply chains and operations of leading companies are particularly vulnerable. This is due to various current trends: Optimization focus on supply chain that eliminates or reduces inventory. This depends on maintaining narrow contact with suppliers, customers and transportation in order to achieve quick response. Any failure will put the operation at risk.

- The elimination of routes or alternate suppliers in order to consolidate and obtain quantity discounts. This contributes to cost reduction, but can increase the company’s exposure to risk.

- A lack of integrated focus in decision analysis. Business cases that justify initiatives generally try to consider all the benefits, but do not include all the potential costs.

- The lack of visibility of the most vulnerable points in the operation that can be exposed to any sudden change.

What is the focus that Sintec recommends on risk management?

The two key concepts for defining the organizational focus on risk are redundancy and flexibility.

The concept of flexibility is based on interchangeability, the capacity to exchange elements in the supply chain in an agile and efficient way. Flexibility can be described as the capacity to create redundancy without incurring the costs that this implies. Following are some examples of flexibility:

- Standardization of processes and installations throughout the supply chain

- Interchangeability of components and finished products

- Integration of different supply chain elements to one decision maker

- Postponement strategies

- Alignment of the sourcing strategy to the supplier type

- Collaboration with members of the extended chain

There also is a fundamental factor that makes a big difference, and that is the organizational culture in light of risk. There are various characteristics that all organizations must have if they want to guarantee a quick, efficient response to any disruptive event:

- Continuous communication between highly-informed employees

- Decentralized decision-making

- Conditioning for facing disruptions

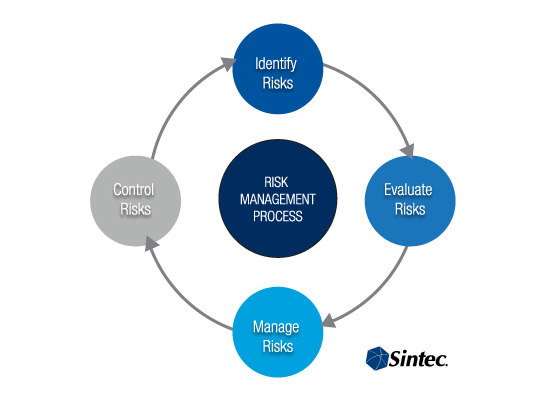

Any organization operating in today’s environment has a complex supply chain that is subject to numerous risks of disruption, the effects of which can be significant and long-lasting. Sintec helps organizations to formulate a risk management strategy based on a rigorous understanding of the vulnerable points of the extended chain, and the application of restraint and mitigation plans based on the proper combination of redundancy and flexibility. We also favor a cultural change that considers risk as part of daily challenges and not as something that is impossible to prepare for.

Recommended publication: